• Barry Mounts are vibration-dampening technology designed to reduce mechanical vibrations and the risk of engine failure due to unbalanced and misaligned components.

• Advanced sensor technology provides real-time monitoring for measures such as temperature, pressure, and fuel consumption to predict impending failures.

• Enhanced inspection techniques such as digital radiography and ultrasonic inspections can reveal structural defects.

• Proper implementation of these technologies includes analyzing needs, training personnel, regular maintenance, and ensuring compliance with regulations.

Aircraft engine failure is a nightmare scenario for any airline or aircraft operator. While it is true that modern aircraft are designed for redundancy, with multiple engines or systems backing up primary functions, the fact remains that preventing engine failure is paramount in ensuring safe and reliable flights.

With that in mind, here are groundbreaking technologies making significant strides in reducing the risk of aircraft engine failure, helping business executives, managers, and bosses maintain confidence in the smooth operation and safety of their fleet of aircraft.

Advanced Sensor Technology

Improved sensor technology plays a vital role in preventing engine failure. Real-time monitoring through advanced sensors continuously measures factors such as temperature, pressure, and fuel consumption.

These readings provide valuable insights into the engine’s performance and help predict impending failures, enabling maintenance crews to intervene before a catastrophic malfunction occurs. More advanced sensors are also being developed to assist in better understanding the behavior and conditions within the engine during normal and abnormal operations.

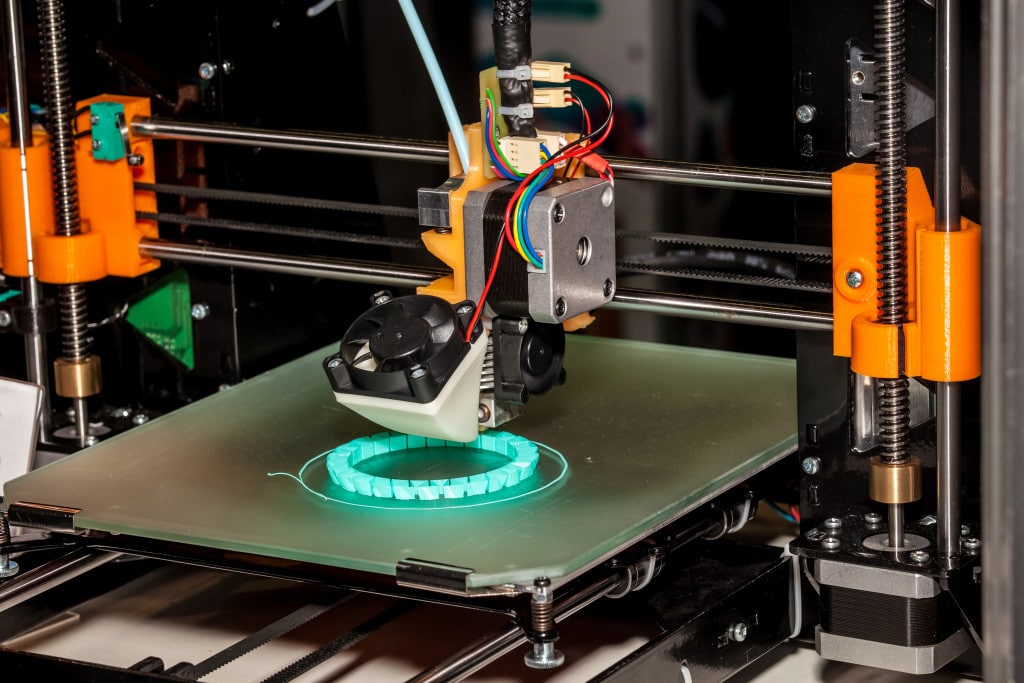

3D Printing and Additive Manufacturing

3D printing, also known as additive manufacturing, has taken the aerospace industry by storm with its ability to create precisely engineered components quickly and efficiently. 3D printing for aircraft engine components saves time and money in production and allows for innovative designs that may have been impossible or too expensive to create through traditional manufacturing methods.

With the flexibility and precision that additive manufacturing provides come improved reliability and reduced risk of engine failure, as engines designed with these cutting-edge methods can better withstand the rigors of flight.

Barry Mounts

Barry mounts are a type of vibration-dampening technology designed to reduce mechanical vibrations in aircraft engines. They have been proven to significantly reduce the risk of engine failure due to unbalanced and misaligned components.

Barry mounts can also be used with existing engines, eliminating the need for costly overhauls or replacements. Investing in barry mounts is one of the most cost-effective ways to reduce engine failure, as well as enhance both aircraft performance and fuel efficiency.

Enhanced Inspection Techniques

Efficient inspection of aircraft engines is crucial in identifying and addressing potential issues before they lead to engine failure. Traditional inspection techniques, such as visual and manual inspections, are often time-consuming and may be limited in their ability to accurately assess an engine’s condition.

To address this, new inspection technologies have emerged to provide enhanced detection, imaging, and accuracy. Techniques such as digital radiography, eddy current testing, and ultrasonic inspections can reveal structural defects or damage that wouldn’t be visible to the naked eye, ensuring that necessary maintenance can be performed before a minor issue leads to engine failure.

Proper implementation of these technologies

Now that you know the key technologies that can reduce the risk of aircraft engine failure, it is important to ensure they are properly implemented throughout your organization. This includes the following steps:

Analyzing your needs

Start by assessing your aircraft maintenance strategy and identifying areas where the technologies mentioned above could be used to enhance reliability and safety.

Training personnel

Training personnel on the proper use and maintenance of the equipment is essential in ensuring its maximum efficacy. You should insist on thorough training and continuous education to ensure that staff has the knowledge, skills, and awareness necessary to properly utilize the technologies.

Regular maintenance

Routine maintenance of aircraft engines is critical in keeping them operating efficiently and reducing the risk of engine failure. This includes regular inspections, checks for wear and tear, cleaning of components, and replacement or repair of faulty parts.

Ensuring compliance with regulations

Adherence to all regulatory requirements is paramount in ensuring safe and reliable aircraft engine operation. This includes compliance with the FAA’s standards and requirements, as well as any applicable international regulations.

By knowing how to properly implement the technologies discussed above into your maintenance strategy, you can help ensure the smooth operation and safety of your aircraft.

By leveraging technology and adhering to all applicable regulations and standards, aircraft operators can ensure the smooth operation of their engines. This will result in a safer flight experience for passengers while reducing the risk of engine failure. Implementing these technologies requires understanding your needs and proper training for personnel on how to use them correctly.

With regular maintenance checks and inspections, you can help keep your fleet running smoothly without any issues or catastrophic malfunctions. By following these steps, you’ll be able to reduce the risk of aircraft engine failure significantly!