- Electrical insulation monitoring is crucial for reducing the risks of electric shocks and fires.

- Residual current devices (RCDs) help to quickly disconnect the power supply in case of leakage or imbalance, preventing electrocution.

- Surge protection devices (SPDs) protect sensitive devices from unexpected power surges.

- Infrared thermography helps identify potential electrical faults before they become serious.

- Lockout/tagout systems ensure that energy sources are isolated during maintenance or repair activities, protecting workers from electrical shocks.

When running a business, electrical safety should be a top priority. Electrical accidents can lead to injuries, property damage, and even loss of life. Therefore, implementing the right technology is crucial to ensure electrical safety in your business. This guide will explore the top five technologies that can help you maintain a safe electrical environment.

1. Electrical Insulation Monitoring

One of the key aspects of electrical safety is monitoring the insulation of electrical systems. Faults in insulation can lead to electric shocks and fires. To mitigate this risk, you can implement electrical insulation monitoring systems.

Here are the benefits of electrical insulation monitoring:

Improved Safety

Electrical insulation monitoring systems help to reduce the risks of electric shocks and fires by detecting any faults in insulation in real time. This helps you to take necessary action quickly, improving overall safety standards in your workplace.

Cost Savings

Insulation breakdowns can lead to costly repairs or even complete system replacements, which can greatly burden your budget. Electrical insulation monitoring systems can help you save costs from unexpected repairs and replacements by detecting any issues before they become severe.

Regulatory Compliance

Many industries must comply with specific regulations regarding electrical safety in their workplaces. Implementing an electrical insulation monitoring system ensures that you comply with regulations and prevent fines or other penalties for non-compliance.

Peace of Mind

Knowing that your workplace is safe and compliant with electrical regulations can give you the peace of mind to focus on other aspects of running your business, knowing that any insulation issues will be detected and taken care of quickly.

2. Residual Current Devices (RCDs)

Residual Current Devices, commonly known as RCDs or GFCIs (Ground Fault Circuit Interrupters), are essential devices for electrical safety. They monitor the current flow in a circuit and quickly disconnect the power supply if they detect any leakage or imbalance. RCDs are particularly useful in areas where water is present, such as kitchens, bathrooms, or outdoor workspaces. By promptly cutting off the power, RCDs prevent electric shocks and significantly reduce the risk of electrocution.

An RCD is usually installed at the main power switchboard or in an individual circuit. It’s a small box with two wires connected to it, and when there’s an imbalance of current A (the phase current) and B (the neutral return line), it will trip off automatically. This prevents dangerous electric shocks from occurring due to contact with energized equipment.

3. Surge Protection Devices (SPDs)

Power surges can occur due to lightning strikes, utility grid fluctuations, or electrical faults. These surges can damage electronic equipment, disrupt operations, and pose safety risks. Surge protection devices (SPDs) protect your business’s electrical infrastructure and equipment from surges. SPDs divert excess voltage to the ground, preventing it from damaging sensitive devices. Installing SPDs at key points in your electrical system, such as main distribution panels or individual equipment, can safeguard against unexpected power surges.

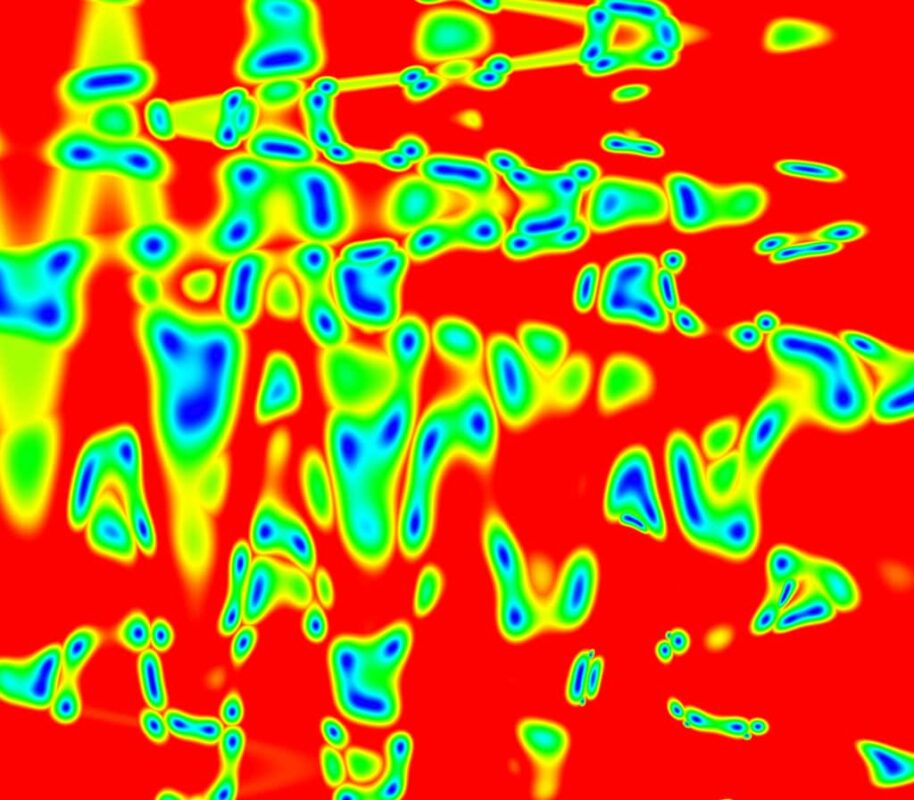

4. Infrared Thermography (Electrical Infrared Testing)

Investing in high-quality electrical infrared testing can help you identify potential electrical faults before they become serious. Infrared thermography is a non-invasive method that enables technicians to detect hot spots in electrical systems, such as overloaded circuits or failing components. Electrical infrared testing helps you take preventive action before any major damages occur and ensure the safety of your business’s electrical systems.

5. Lockout/Tagout Systems

Lockout/Tagout (LOTO) systems are critical for the safety of maintenance workers and technicians who service electrical equipment. LOTO systems ensure that energy sources are isolated and effectively locked or tagged during maintenance or repair activities. This prevents accidental re-energization of equipment, protecting workers from electrical shocks and injuries. LOTO systems typically involve lockout devices, tags, and specific procedures that must be followed to safely de-energize and work on electrical systems.

Ensuring that all personnel involved in the LOTO process are adequately trained and understand the procedures is essential. Training should include suitable instruction on the use of locks, tags, and other devices necessary for effective lockout/tagout implementation and proper procedure review. Workers should also be instructed on the risks of not using a LOTO system when working on energized equipment.

To Wrap It Up

Electrical safety is paramount in any business setting, as it directly impacts the well-being of employees, the protection of assets, and the continuity of operations. You can significantly reduce the risks associated with electrical accidents by leveraging advanced technologies, such as electrical insulation monitoring, residual current devices, surge protection devices, infrared thermography, and lockout/tagout systems. Investing in these technologies safeguards your business and demonstrates your commitment to providing a safe working environment for your employees. Remember, prevention is always better than dealing with the consequences of an electrical incident.